Sammenføyning av metallplater

Tettingssystemer for konstruksjonsfuger og forhåndsbestemte sprekkfuger, stoppplater og tilbehør samt fugebånd og vårt aktive fugebånd MASTER-MultiFlex MMF.

Belagte skjøteplater: er testet og godkjent av Institutes for Material Testing.

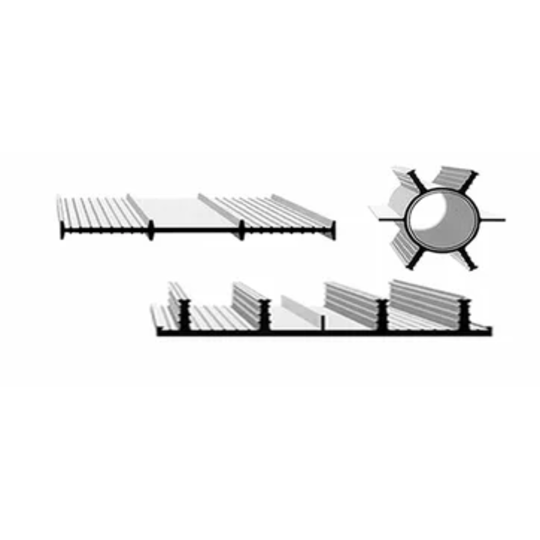

Sprekkdannende profiler: som er utformet for å skape og samtidig tette en sprekk.

Stopend-paneler: for forskaling av vegger og fundamenter.

Ubelagte metallplater kalt "small coils": har blitt installert i flere tiår. Testsertifikater er ikke tilgjengelige.

For vanntetting av konstruksjonsfuger i armerte betongkonstruksjoner...

Sprekkfremkallende elementer. En sprekk vil bli generert og forseglet i samme øyeblikk....

Avslutningsplater for panelskjøter i metall ABS. Profiler for plasstøpt betong...

Her finner du tilbehør som fugevinkler eller skjøtebeslag for skjøteplater og skjøtebånd, samt vår lydisolerende skjøt og tilhøren...

Fugeplater galvanisert eller svart og passende koblinger samt koblinger for fugebånd....

Aktiv fugetape for vanntetting av konstruksjonsfuger...

Svært elastiske skjøtebånd / vannstoppere i henhold til fabrikkstandard...

What role do metal waterstops and shuttering elements play in reinforced concrete construction?

The white tank is a structure in which the concrete not only fulfils the load-bearing function but also acts as a seal against pressing and non-pressing water (watertight concrete). The requirements for this construction method are regulated in the WU guideline (watertight concrete structures) from the German Committee for Reinforced Concrete (DAfStb). The impermeability of the joints plays a special role in the construction of a white tank. These must be suitably sealed in accordance with the WU guideline, depending on the type of joint. Proof of usability is provided in the form of an abP (general building authority test certificate). The issue of the test certificate provides proof of functionality and defines the area of application for the respective product.

What are metal waterstops and shuttering elements used for?

Metal waterstops and coated metal sealing sheets are particularly suitable for sealing construction joints. They have proven themselves in practice for many years. The use of uncoated metal waterstops is regulated in the WU guideline.

The areas of application of coated sealing sheets are defined in the general building authority test certificates (abP). In the Waterproofing Directive, AbP's are required as proof of usability and are a prerequisite for use. The German Concrete and Construction Technology Association (DBV) has summarised extensive, supplementary explanations on coated metal waterstops in the leaflet "Coated metal waterstop systems".

Shuttering elements are used as so-called permanent formwork. They are used to separate concreting sections from each other. They are also sealed directly with an integrated sealing layer.

Predetermined crack profiles and elements are used to specifically create cracks (so-called "predetermined crack joints") and, if necessary, to seal them directly. These predetermined cracks in the wall or base prevent unplanned cracks in the component.

How do metal waterstops and shuttering elements work?

Our VB sealing sheets have a special adhesive coating and bond with the fresh concrete. They are integrated into the base in the area of the construction joint and seal it reliably.

Shuttering elements are used as permanent formwork and create a rough or toothed surface due to the expanded metal used. Shuttering elements with an integrated sealing layer also prevent water from penetrating these areas.

With the predetermined crack elements, the cross-section of the wall or base is weakened to such an extent that a targeted crack is created at this point in order to remove stresses from the component and thus prevent cracks in undesired areas. The cracks created in this way are sealed directly by the integrated sealing layer.

engelsk

engelsk